Blue Mounds/Fahrni Cheese Factory

|

Blue Mounds Township

|

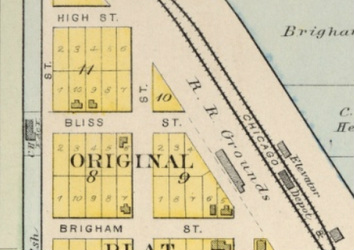

2987 Mounds Rd,

Blue Mounds WI 53517 Off site resource

Road View and Map |

Operated: <1890 - >1949

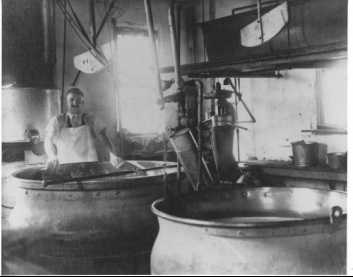

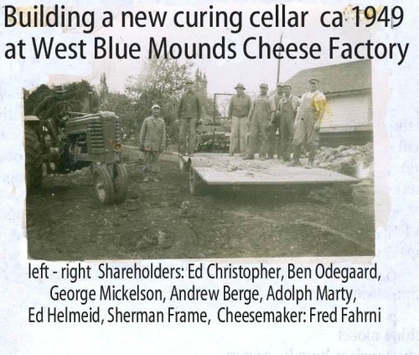

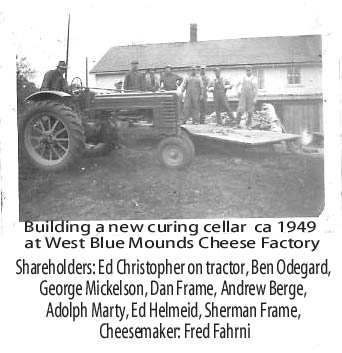

Cheesemakers: Gottlieb Werren (1919-1941) won Dane Co. contest for cheese factories "Beautify Your Surroundings" 1926; Fred Fahrni

Cheese Types: Brick, Swiss

Patrons: Ed Christopher, Ben Odegaard, George Mickelson, Andrew Berge, Adolph Marty, Ed Helmeid, Sherman Frame, Dan Frame. Ronnie Fargo; Harold Berg Chase. Owner Roach. & Seeber, Waterloo.

Notes: Biennial report of the Dairy and Food Commissioner of WI: Blue Mounds 1901, 1906, 1909, 1913, 1922, 1930. Also a creamery in 1909.

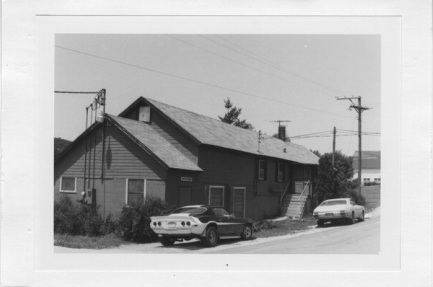

Wisconsin Historical Society, Wisconsin Architecture and History Inventory- Architectural Style: Other Vernacular. Wall Material: Wood.

Wisconsin Historical Society, Wisconsin Architecture and History Inventory- Architectural Style: Other Vernacular. Wall Material: Wood.

Newspaper photographs and following article from Blue Mounds Historical Society.

The following letter was a recollection by Joyce Fahrni Ferrell, Leesburg, FL, who lived in the West Blue Mounds Cheese Factory. Fred Fahrni, her father, was the cheesemaker. He produced Swiss cheese at this time.

With thanks for information contributed by Robert Mueller, Verona, WI, Vern Fahrni, Elizabeth, CO and Lyle Fahrni, Arena ,WI 2009. Blue Mounds Historical Society

"The Whey Tank

You could smell it all over town. One person said it smelled like stinky feet, another described rotten or sour milk, one recalled an odor similar to vinegar while most others just spit out the descriptive word “pee-ew!” The odor being described was emanating from the outdoor whey tank at the local cheese factory.

The whey tank was on a pole framework so it stood above the wagons or trucks which daily hauled cans of milk to the factory. The huge tank was made of 2 inch thick oak boards and shaped like a barrel with an open top. Insects of all kinds were plentiful in the open whey tank. It was not uncommon for an occasional bird or rat to fall into the tank.

The boards of the all-important whey tank became saturated with aged, spoiled whey as new whey was added daily. Occasionally it needed to be emptied completely because as the whey fermented the solids not only coated the inside of the tank, but settled to the bottom and sometimes plugged the dispensing hose.

Whey was dispensed by gravity. A long fat hose was attached to a hole at the bottom of the tank. The hose end was placed into a milk can or other container and a rope was pulled to release the valve to let whey flow into a container in the vehicle below.

Whey, fresh and hot before it was pumped into the whey storage tank was delicious and nutritious; good to drink. Each farmer was allotted approximately the same amount of whey as he had brought milk. Whey, a by product of making cheese from milk, was an important food source for farm animals and farmers jealously guarded the amount of whey to which they were entitled. Pride in getting up early in the morning and milking cows was part of the culture of living the dairy farm life. Another reason to be early delivering milk to the factory was all farmers wanted to be first to collect their whey while the supply lasted. It was possible the last farmer to deliver his milk to the factory each morning, would be shorted; the whey would be gone and so he would not receive his full share.

One man said that at their factory, his father, the cheesemaker, invented a system whereby when the farmer had filled the cans with his allotted amount of whey, a bell would ring. The others farmers waiting their turn at the tank would hear the bell and shame the first farmer into not taking more than his share.

It was necessary for the cheesemaker to add some water to the whey to make it equal the amount of milk that was delivered. By adding water at the source, it saved the farmer the work of hauling water to his feeding station on the farm.

The process of delivering milk and collecting whey, also, served as a social event as farmers exchanged news of the day before going home to breakfast and a long day of hard work.

In the first half of the 20th century, cheese whey was primarily used for mixing with ground corn and other grains and fed to pigs. The resulting porridge was called slop and pigs loved and thrived on it. It was also fed to heifers and other farm animals on a more limited basis.

After mid century, farmers became more specialized and concentrated on fewer types of animals. As fewer dairy farmers raised pigs, the need for whey lessened and the whey became an excess by-product which in some instances farmers spread on the fields as a fertilizer.

Soon, however, it became a commodity that could be sold. Plants dedicated to processing whey appeared and huge clean tanker trucks collected fresh whey directly from the cheesemaking operation on a daily basis. The whey was then processed into a dry whey product and re-sold for use in many human food products. The days of the stinky cheese factory whey tank were numbered. "

The following letter was a recollection by Joyce Fahrni Ferrell, Leesburg, FL, who lived in the West Blue Mounds Cheese Factory. Fred Fahrni, her father, was the cheesemaker. He produced Swiss cheese at this time.

With thanks for information contributed by Robert Mueller, Verona, WI, Vern Fahrni, Elizabeth, CO and Lyle Fahrni, Arena ,WI 2009. Blue Mounds Historical Society

"The Whey Tank

You could smell it all over town. One person said it smelled like stinky feet, another described rotten or sour milk, one recalled an odor similar to vinegar while most others just spit out the descriptive word “pee-ew!” The odor being described was emanating from the outdoor whey tank at the local cheese factory.

The whey tank was on a pole framework so it stood above the wagons or trucks which daily hauled cans of milk to the factory. The huge tank was made of 2 inch thick oak boards and shaped like a barrel with an open top. Insects of all kinds were plentiful in the open whey tank. It was not uncommon for an occasional bird or rat to fall into the tank.

The boards of the all-important whey tank became saturated with aged, spoiled whey as new whey was added daily. Occasionally it needed to be emptied completely because as the whey fermented the solids not only coated the inside of the tank, but settled to the bottom and sometimes plugged the dispensing hose.

Whey was dispensed by gravity. A long fat hose was attached to a hole at the bottom of the tank. The hose end was placed into a milk can or other container and a rope was pulled to release the valve to let whey flow into a container in the vehicle below.

Whey, fresh and hot before it was pumped into the whey storage tank was delicious and nutritious; good to drink. Each farmer was allotted approximately the same amount of whey as he had brought milk. Whey, a by product of making cheese from milk, was an important food source for farm animals and farmers jealously guarded the amount of whey to which they were entitled. Pride in getting up early in the morning and milking cows was part of the culture of living the dairy farm life. Another reason to be early delivering milk to the factory was all farmers wanted to be first to collect their whey while the supply lasted. It was possible the last farmer to deliver his milk to the factory each morning, would be shorted; the whey would be gone and so he would not receive his full share.

One man said that at their factory, his father, the cheesemaker, invented a system whereby when the farmer had filled the cans with his allotted amount of whey, a bell would ring. The others farmers waiting their turn at the tank would hear the bell and shame the first farmer into not taking more than his share.

It was necessary for the cheesemaker to add some water to the whey to make it equal the amount of milk that was delivered. By adding water at the source, it saved the farmer the work of hauling water to his feeding station on the farm.

The process of delivering milk and collecting whey, also, served as a social event as farmers exchanged news of the day before going home to breakfast and a long day of hard work.

In the first half of the 20th century, cheese whey was primarily used for mixing with ground corn and other grains and fed to pigs. The resulting porridge was called slop and pigs loved and thrived on it. It was also fed to heifers and other farm animals on a more limited basis.

After mid century, farmers became more specialized and concentrated on fewer types of animals. As fewer dairy farmers raised pigs, the need for whey lessened and the whey became an excess by-product which in some instances farmers spread on the fields as a fertilizer.

Soon, however, it became a commodity that could be sold. Plants dedicated to processing whey appeared and huge clean tanker trucks collected fresh whey directly from the cheesemaking operation on a daily basis. The whey was then processed into a dry whey product and re-sold for use in many human food products. The days of the stinky cheese factory whey tank were numbered. "

Higher quality reproductions of some of the MHAHS's images are available for a small fee - contact our Research Center.